A more complex template...

Another milestone for iteration3d!

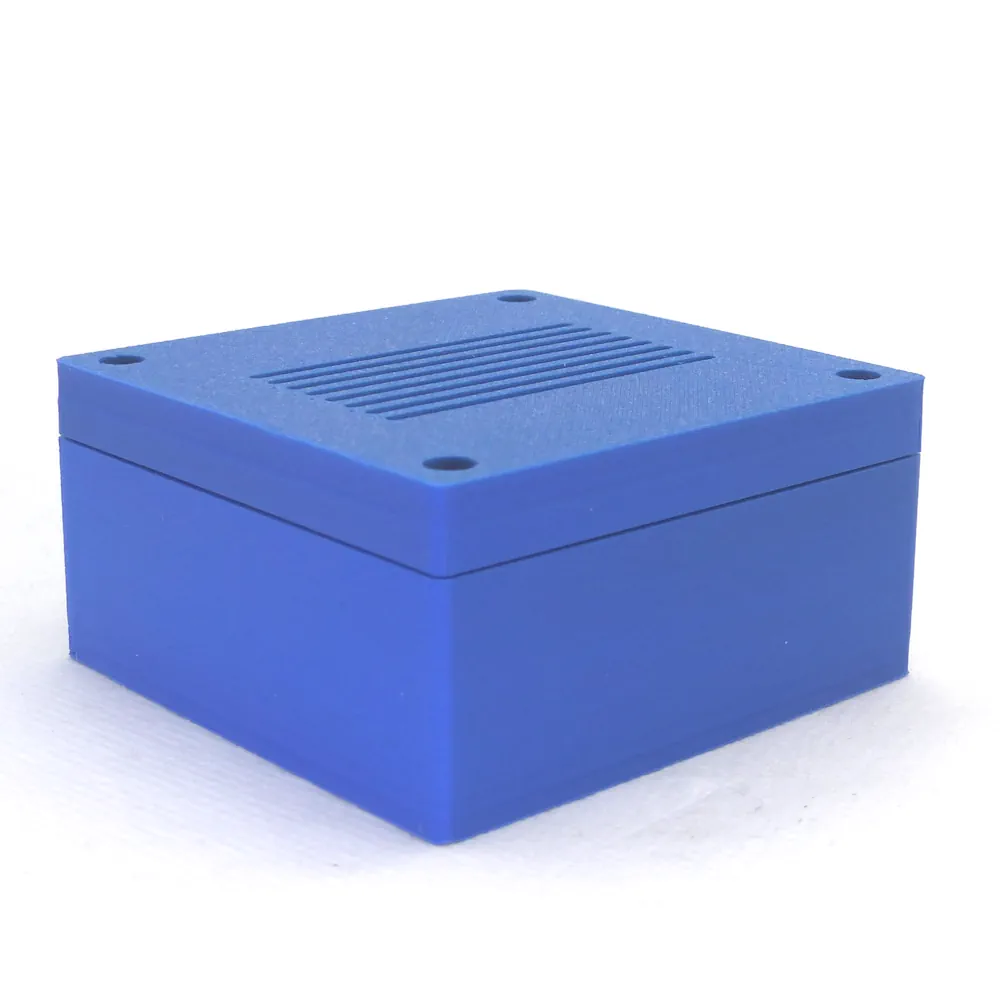

A new, more complex template now allows the generation of enclosures with a screwed lid, fully customizable.

Dimensions, lid height, wall thickness, adjustment margins, ventilation levels… every parameter can be configured to suit your needs.

This model also introduces support for assembly with screws, with precise placement and optimized housing.

Iteration3d continues its progression toward more technical, multi-part models configurable on demand.

Now it’s your turn to generate yours!

As July begins, we’re tackling a more complex model with On-demand generation of an enclosure with screw-mounted lid !

Why more complex?

The platform continues to move forward step by step. The previous template, On-demand generation of a round box with lid , paved the way for models consisting of multiple parts forming a single unit.

But let’s admit it — that was still a fairly “basic” model. With this new screw-lid enclosure template, we’re stepping into something more refined, more elaborate. Let’s take a closer look at what this template has to offer.

The template in detail

As the name suggests, this template produces enclosures made up of two elements: the base and the lid. These two parts are held together by 4 M3 screws with hex socket and cylindrical head (DIN 912).

Unsurprisingly, the basic parameters are available:

- Length

- Width

- Height

It is also possible to define the wall thickness and the lid height independently. Note that the upper wall of the lid will always be 5 mm thick to accommodate the screw heads.

Please note that the length and width parameters refer to the external dimensions. Let's assume you want an internal space of 80x60 mm and walls that are 3 mm thick. In that case, you will need to set the (external) length to 86 (80+3+3) mm and the width to 66 mm.

Then come some useful parameters: the fit clearance and the screw margin. Every 3D printer knows that the final measured dimensions of a printed object tend to be slightly smaller than their theoretical values — and this can vary depending on the material. That’s why the fit clearance allows for fine-tuning the snap fit. Similarly, the screw margin helps ensure the thread carves into the material just enough — not too much. This parameter can even be negative. And finally, a small chamfer is applied at the entry of the screw holes in the base to make insertion easier.

And best of all, two parameters allow you to add ventilation.

The cooling level parameter lets you choose how much ventilation you want. At 0, no cutouts are generated, so there’s no airflow. At 10, the model includes the maximum number of cutouts. Everything is calculated by the generation engine.

The cooling zone(s) parameter defines where the cutouts will be applied:

- 0: no cutouts

- 1: cutouts on the lid

- 2: cutouts on the base

- 3: cutouts on both

Finally, for aesthetic purposes, a small chamfer is applied to the four corners of the enclosure.

We told you this template was more advanced!

Some examples

Here are a few examples of screw-lid enclosures generated by the platform:

Now it’s your turn to generate the enclosure you've been waiting for!